VTRAC catalyst assistant is used in the catalytic cracking unit as an auxiliary agent, and can be injected into the regenerator together with the catalyst.

VTRAC catalyst assistant can be injected into the regenerator together with the catalyst, which is simple and convenient, and the added amount accounts for 5%-10% of the system storage.

VTRAC catalyst assistant is made of active components and carriers, and its active components are composite metal oxides.

The carrier is a silicon-alumina material with a pore size gradient distribution, and the synergistic effect of both can effectively improve its metal trapping ability.

During the catalytic cracking process, heavy metals are captured and reacted by their active components to generate inert and harmless compounds or alloys to protect the catalyst to maintain the original activity and selectivity.

Characteristics as follows:

1. Strong ability to capture metal vanadium and resistance to heavy metals, vanadium capture coefficient > 10%;

2. Reduce the coke and hydrogen yields in the device;

3. Excellent wear resistance, will not adversely affect the fluidization and operation of the device.

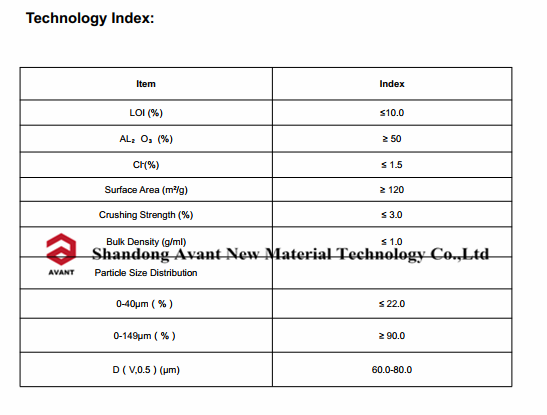

Technology Index: