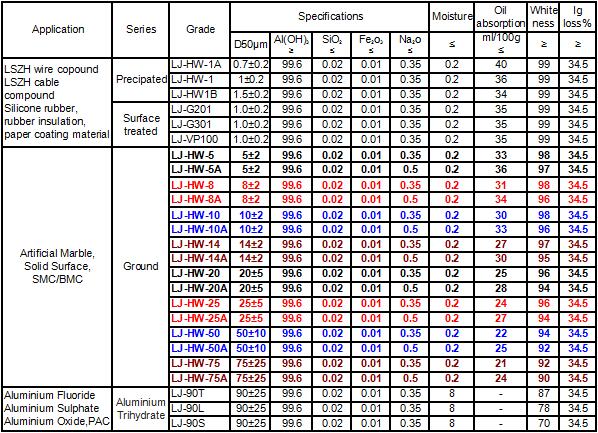

Surface Treated Aluminum Hydroxide for Rigid PVC Plastic can also be significantly reduced the smoke density of plastic, and the mechanical properties of the material have little effect, the dosage is in the range of 20 to 30 parts.

With the development of the building materials industry, rigid polyvinyl chloride (PVC) plastic products (wire grooves, pipes, doors and windows and other shaped materials) have been widely used, becoming an indispensable material in the national economy and daily life. However, when it burns, it produces a lot of smoke, decomposing toxic and corrosive gases, suffocating, and is the main cause of death in fires.

The application of ATH to PVC effectively overcomes the above shortcomings. Surface Treated Aluminum Hydroxide for Rigid PVC Plastic can improve the oxygen index of PVC plastics, and Surface Treated Aluminum Hydroxide for Rigid PVC Plastic can also be significantly reduced the smoke density of plastic, and the mechanical properties of the material have little effect, the dosage is in the range of 20 to 30 parts.