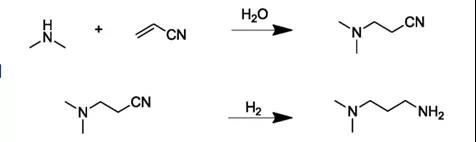

The mainstream synthetic route for DMAPA is:

1. Dimethylamine and acrylonitrile are used as raw materials to obtain dimethylaminopropionitrile (DMAPN) by Michael addition. DMAPN is prepared industrially by adding about 2% of the total mass of water to facilitate the addition reaction and azeotropic removal of excess dimethylamine; 2. DMAPA is prepared by catalytic hydrogenation of DMAPN obtained from the first distillation step under high pressure conditions (Figure below).

DMAPA hydrogenation reaction:

In the second step of hydrogenation to prepare DMAPA, side reactions occur, the by-products of which are mainly secondary amine bis - DMAPA and tertiary amine tri - DMAPA. In order to suppress the by-products, aqueous caustic soda or liquid ammonia of 12-16% of the catalyst mass is added. The use of aqueous caustic soda and liquid ammonia generates a large amount of waste water, which is difficult to degrade and increases the burden of reprocessing.

The use of caustic soda and liquid ammonia generates a large amount of waste water, which is difficult to degrade and increases the burden of post-treatment.