At present, the residual oil hydrogenation technology is mainly divided into four categories according to different types of reactors: fixed bed, fluidized bed, slurry bed and moving bed.

Among them, the fixed bed residue hydrogenation technology is mature, simple and reliable, accounting for more than 75% of the current total residue hydrogenation processing capacity.The ebullated bed residue hydrogenation technology has the advantages of small pressure drop in the reactor bed, uniform temperature distribution, high mass and heat transfer efficiency, and flexible operation.It can effectively solve the problems of short operation cycle in the traditional fixed bed hydrogenation technology when dealing with inferior residual oil raw materials.It is the preferred technology for the efficient conversion of heavy oil at present.Sinopec (Dalian) Research Institute of Petrochemical Industry Co., Ltd. (FRIPP, referred to as "Dalian Institute") started the research on ebullated bed and fixed bed residual oil hydrogenation technology in the 1960s and 1980s respectively, and is the earliest domestic research on residual oil hydrogenation technology. scientific research institutions.

In 1998, Dalian Research Institute completed the development of a complete set of fixed-bed residue hydrogenation technology (S-RHT®) with independent intellectual property rights.And relying on this technology to design and build a 2 million tons/year residual oil hydrotreating unit in Maoming, the first operation was successful, and the technical performance reached the international advanced level.

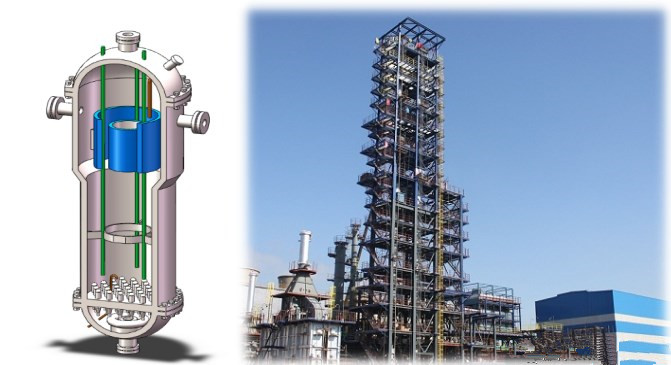

After nearly 40 years of development, S-RHT® fixed bed residue hydrotreating technology continues to innovate and make breakthroughs,which has strong competitiveness in the competition with similar technologies in the world.In the 1960s and 1970s, Dalian Institute began to engage in the research and development of domestic fluidized bed residue hydrogenation technology.In 2004, the research and development of domestic fluidized bed technology entered the fast lane.With the strong support of Sinopec Group Corporation, Dalian Research Institute has completed the laboratory development and pilot scale-up of the domestic ebullated bed hydrogenation process and supporting catalysts.In 2010, Dalian Institute, Guangzhou Engineering Company and Jinling Branch formed a joint research unit to promote the industrial application of the domestic STRONG fluidized bed hydrogenation complete technology.In 2015, the 50,000-ton/year STRONG fluidized bed industrial demonstration plant with completely independent intellectual property rights was built in Jinling Branch and successfully started at one time,which completed the first 10,000-ton industrial demonstration operation of domestic fluidized bed hydrogenation technology.While verifying the engineering scale-up law of domestic fluidized bed hydrogenation technology, a wealth of data and experience have been accumulated for the technology scale-up.In 2018, Dalian Institute's STRONG fluidized bed hydrogenation technology was listed as one of the top ten brands of Sinopec.In 2020, the 500,000-ton/year STRONG fluidized bed hydrogenation industrial plant was completed and put into industrial operation. It has been in stable operation for nearly 2 years.After 50,000 tons and 500,000 tons of industrial plants were scaled up step by step, the maturity and reliability of the complete set of domestic fluidized bed hydrogenation technologies have been fully verified.At present, the 2.8 million ton/year and 2 million ton/year industrial plants adopting the complete set of domestic fluidized bed hydrogenation technology are in the detailed design stage and are expected to be completed and put into operation in 2024.